|

Re-conditioned Scott con-rods - November 2015

Re-conditioning rods is not a small job...and it requires so many 'set-ups' that you really have to do a batch.

A Scott connecting rod needs to run squarely on its narrow big end rollers and any deviation from that causes the rollers to want to twist into the tightest side and rub against the adjacent 'roller plate'. If it's bad enough this ends in overheating, distortion, anealing and bearing surface break-up. Blue rollers, blue roller plates and blue big ends are quite common to see where misalignment has been introduced.

So, the Scott rod is quite a critical item because the little end has to be exactly square to the big end ring. That should be straightforward then...

Well, yes it is. Straightforward, but time consuming.

You see the big end bearing track is too narrow to control the rod's position. The position is really dictated by two other component/ fit relationships: the little end bush and the roller plates.

The little-end bush needs to be very good in terms of it's alignment in both 'bend' and 'twist' conditions; errors in either condition can cause problems at the big end.

But what so you bore the little end in relation to? The big end of course!

but what part of the big end?

This again is important. The roller plates act against the sides of the big end of the rod. They are control plates. The big end 'ring' is a through hardened ring which is pressed into the big end bore and ground to size. Many rings are not pressed in to this bore squarely. Then you have a bearing track which is not square to the very faces which are supposed to be effortlessly controlling its position. Given these facts, how are you supposed to bore the little end... to what?

Obviously you need to start again.

The big end ring is removed, as is the little end bush.

The side of the big end is stoned to remove raised points, especially where rings have been staked to try to retain them.

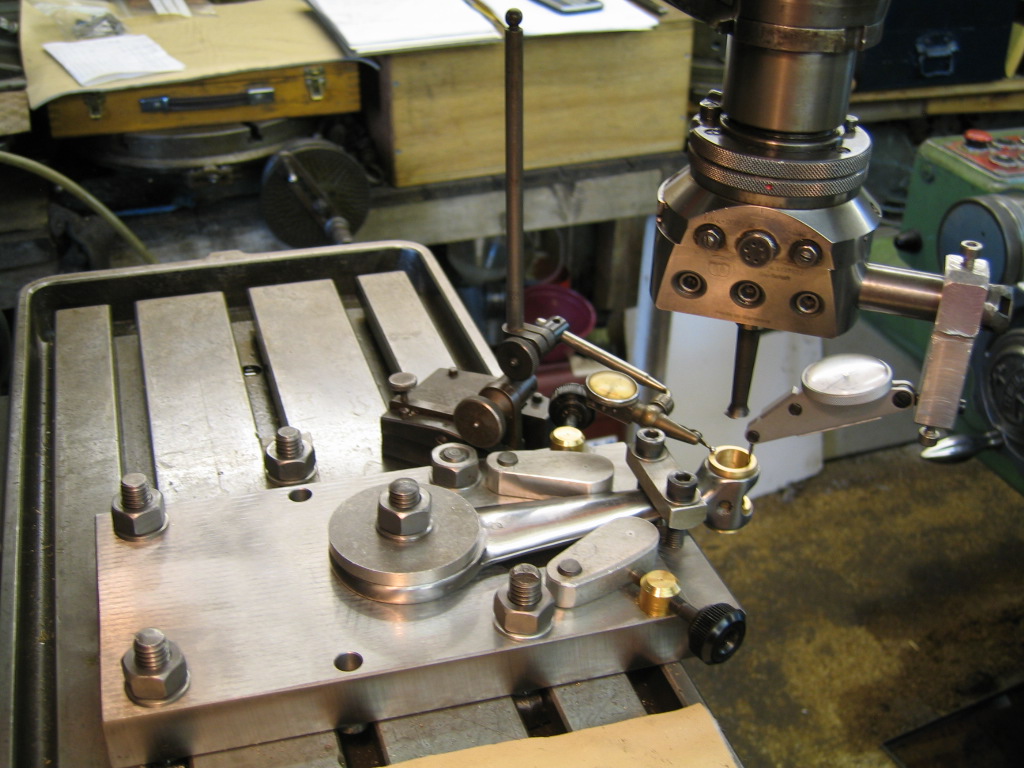

The sides of the big end are cleaned up on a surface grinder.

The big end is re-ground internally to that new side face.

A new ring is ground to suit the big end bore and fitted , making sure that it is pressed absolutely square to the side faces.

The big end is ground to size internally.

The little end is honed and a new bush is fitted to suit.

The little end is bored square to the side face of the big end which defined the position when grinding the big end.

If this is right, then the roller plates just do the very light work of keeping the big end over the rollers.

So, If the alignment of the rod is then good and the crank is running true on an axis square to the block face, and your rollers have correct clearance and the gudgeon pin bore in the piston is bored square to the axis of the piston and the bore is bored square to the lower block mounting face of the block.. then you've got the basis for a good engine!

None of the above can be assumed!

| |

|

|